Why SRT?

World-Class R&D Team

Over 100 professionals (Harvard, Chinese Academy of Sciences alumni) specialize in soft robotics with 10+ years of expertise.

Industry-Leading Innovation

213+ patents (8 international), tens of thousands of experiments. Proprietary database solidifies global leadership in soft robotics.

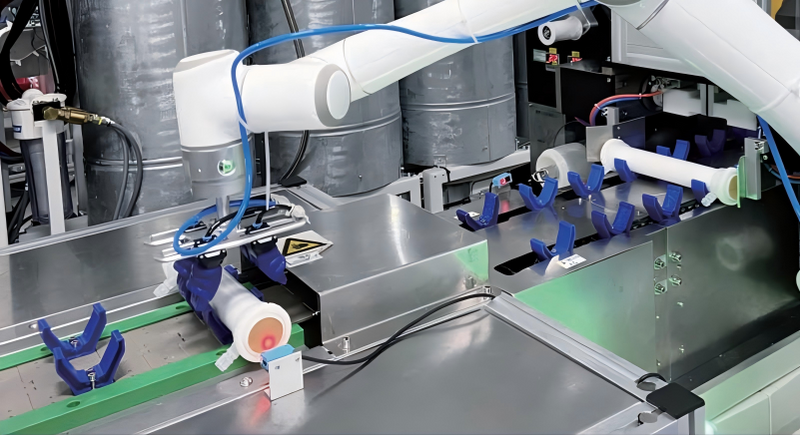

Premium-grade Quality

Self-developed Flexible soft gripper with polymer silicone and adaptive airbag: high repeatability, 3M+ cycles, industrial durability.

Customized Individual Solutions

Serving 500+ leading enterprises in 30+ countries across 20+ industries. Custom end-effector solutions for fragile/irregular item handling via soft robotics.